Updated 6/15/24

Alternative, or renewable, energy is a growing field, with solar, wind, water, geothermal, bioenergy, and nuclear resources all contributing. According to Energy.gov, “the clean energy industry generates hundreds of billions in economic activity and is expected to continue to grow rapidly in the coming years”.

As career opportunities in this field increase, more and more teachers have looked for ways to incorporate renewable energy concepts and practices into their curriculum. And, events such as the KidWind Challenge are a great way to do so.

The KidWind Challenge is a hands-on design challenge that gets students thinking about solutions using wind and solar energy. Student teams design, build, and test solar structures and wind turbines to compete in regional, state, and national competitions.

Building a Better Wind Turbine

Jim Brown’s students have been competing in KidWind challenges for a few years. Brown, a STEM teacher and robotics and competition coach for Sand Creek Middle School in Albany, NY, also has certification as an energy manager from the Association of Energy Engineers and works with schools across the US on, among other things, how to incorporate teaching energy and building operation into the curriculum. He recently secured grant funding for three years that will enable him to be the energy manager for the South Colonie School District in NY.

So, Brown, who also happens to be a member of The Ambassador Group for Pitsco, knows a thing or two about energy and energy alternatives. He also knows some things about how to get students excited about wind energy. And recently, he decided to give his students some new design elements to work with.

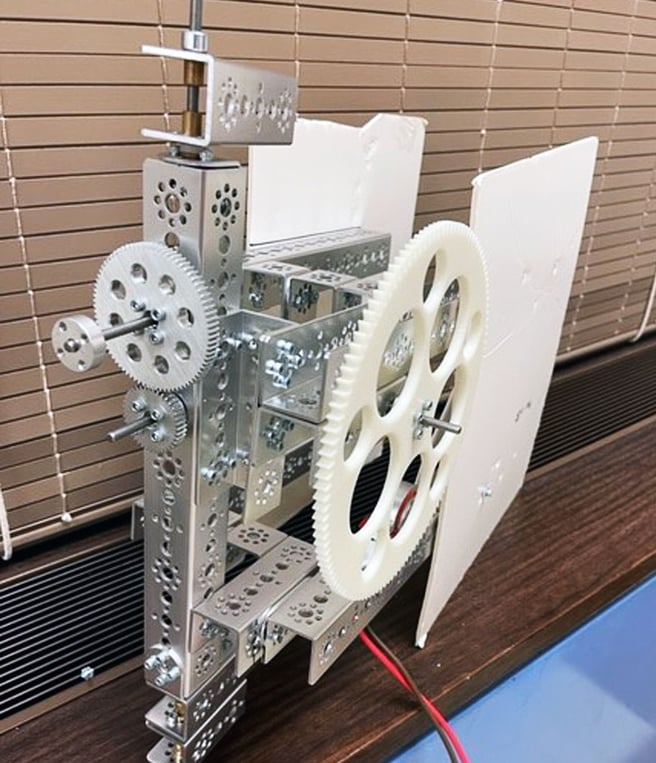

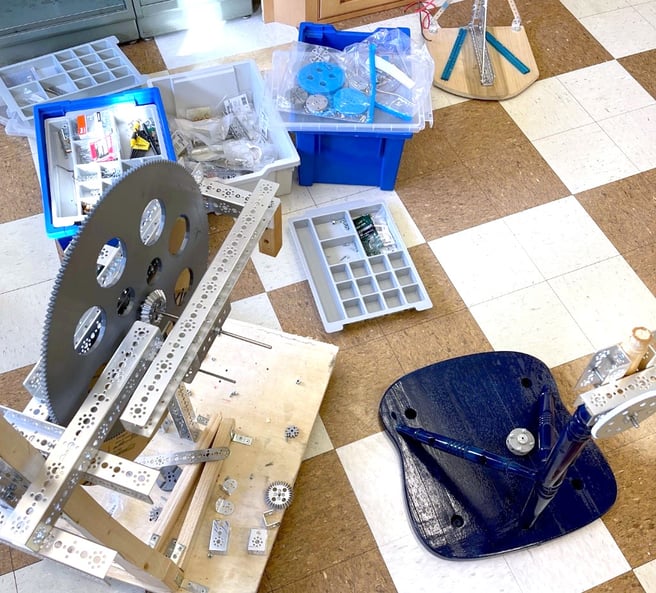

In 2019, Brown began letting the students in his STEM renewable energy class incorporate TETRIX® MAX robotics kits and parts in their wind turbine designs. By October 2021, he had six teams working toward KidWind challenges.

TETRIX MAX, a flexible yet rugged robotics system with aluminum parts, is typically used in robotics classrooms to help students learn to build robots. But, as we’ve seen before, when innovative teachers and creative students get together, “typical” uses often evolve into new, incredible ideas. Simply put, that’s what happened here.

“The TETRIX pieces are the perfect platform to allow students to ‘scratch’ build and test their turbines,” Brown explained. “To make it easier for students, I made a hub from aluminum that bolts to a TETRIX MAX hub, enabling students to insert up to twelve 1/4" dowels, used to attach their wind turbine blades.”

When his students competed in that year’s KidWind challenge, their turbines caught more than just wind, said Brown – they caught the attention of other students and teachers. “Many teachers who saw the TETRIX parts in action went and bought the kits as well.” Eventually, the teams had to move from using hardwood dowels to aluminum dowels “because students were catching so much power from the wind, they began to break the wooden dowels.”

TETRIX Turbines Catching On

The popularity of turbines using TETRIX seems to increase every year. At the 2022 NY regional KidWind Challenge, Brown noticed that several teams had incorporated TETRIX MAX pieces into their wind turbine designs. “From this competition, four of the teams (two high school and two middle school) have been invited to compete at the national level in San Antonio in May, where, I am sure, there will be many, many more turbines sporting TETRIX MAX components,” he said.

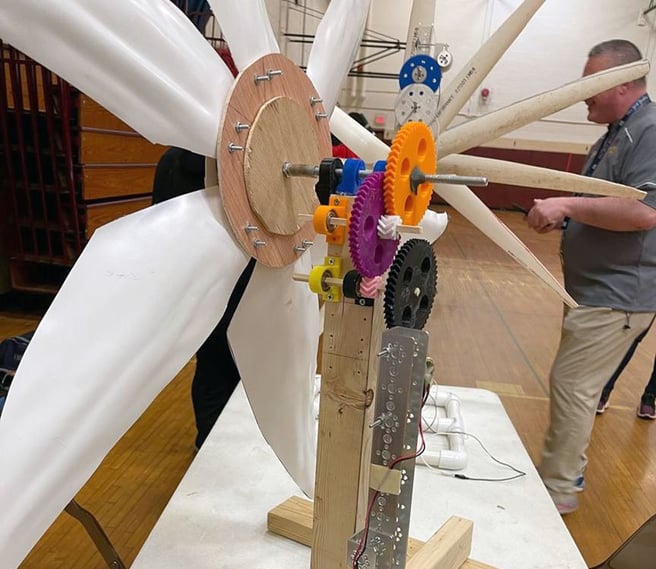

Barry Dusharm’s student teams also used TETRIX MAX in their 2022 KidWind turbine designs. In fact, Dusharm, who teaches at Indian River High School in Philadelphia, NY, said his teams have been incorporating TETRIX MAX for about five years.

“We started using the TETRIX components when I got an engineering elective course approved,” said Dusharm. “I liked the interchangeable nature of the system, which made it easier for students with limited experience with hand tools and gearing to have early success with their designs. And, it kept enthusiasm high.”

While Dusharm’s students have begun using 3-D-printed parts as well, he believes the ease and durability of the TETRIX parts means teams will still be using the high-grade aluminum components in the future. “After our most recent competition, my students are already talking about modifications to blades and gearing, but I fully expect the TETRIX system to remain a large part of their designs,” he said. “The consistency of the TETRIX system makes design work easy and allows fast changes to the design ‘in the field,’ when necessary.”

Both Dusharm and Brown’s teams qualified for the national KidWind events in San Antonio, TX, this May – two high school teams for Dusharm and two middle school teams for Brown. If competition success is any indicator, I’m guessing both Dusharm and Brown’s teams will most likely stick with their winning designs.

Both Dusharm and Brown’s teams qualified for the national KidWind events in San Antonio, TX, this May – two high school teams for Dusharm and two middle school teams for Brown. If competition success is any indicator, I’m guessing both Dusharm and Brown’s teams will most likely stick with their winning designs.

Have you or your students used TETRIX parts in any out-of-the box builds or designs? If so, please share them with us in the comments!

Are your gears turning with exciting ideas? You can get your students started with TETRIX today!

TOPICS: Competitions, ROBOTICS, Engineering, TETRIX Robotics, Hands-on Learning